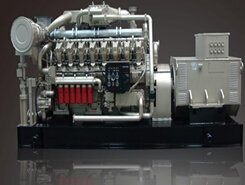

—— 燃料发电设备及机组相关配套设备及配件 ——

全国服务热线:

全国服务热线:

全国服务热线:

全国服务热线:

济南济柴环能燃气发电设备有限公司

济南济柴环能燃气发电设备有限公司

联系电话:罗总18653152416

服务热线:0531-62325028

联系地址:中国(山东)自由贸易试验区济南片区孙村街道经十东路33688号章锦综合保税区联东U谷科创中心5号楼101

1 提高瓦斯发电效率

1. Improve the efficiency of gas power generation

为提高发电效率,在发电机组中可以布置循环式设备,以充分利用机组产生的热量,且其占地面积小,损耗率降低。对发电机组的增压室进行改进,如配合小喷流技术进行瓦斯预处理、采用二体增封闭提高增压效果等。不同的瓦斯浓度会产生不同的发电效率,因此,通过摸索*优的搭配得到适合的瓦斯浓度可以改善整体发电效率。

To improve power generation efficiency, circulating equipment can be installed in the generator set to fully utilize the heat generated by the unit, with a small footprint and reduced loss rate. Improvements have been made to the booster chamber of the generator set, such as using small jet technology for gas pretreatment and adopting two body increased sealing to enhance the boosting effect. Different gas concentrations can result in different power generation efficiency. Therefore, obtaining a suitable gas concentration through exploration and optimization can improve the overall power generation efficiency.

2 提高发电及瓦斯运送安全性

2. Improve the safety of power generation and gas transportation

颁布了煤矿用非金属瓦斯输送管材安全技术条件、瓦斯管道输送自动阻爆装置技术条件和细水雾混合安全输送装备技术规范等10项低浓度瓦斯输送和利用标准,一方面规范煤矿安全生产,另一方面也有助于学者进行这些方面的安全性技术研究。采取加强输送管道的材料安全性、使用专门的漏气监测装置、合理配置防火阻爆装置等措施能使安全事故发生率大大降低。具体如安全设施安设段管道应选用钢管,其他输送管道可选用非金属管,输送管道材料需进行防腐蚀、防漏气、防砸坏、防静电处理。

Ten low concentration gas transportation and utilization standards have been issued, including the safety technical conditions for non-metallic gas transportation pipes used in coal mines, the technical conditions for automatic anti explosion devices for gas pipeline transportation, and the technical specifications for fine water mist mixed safety transportation equipment. These standards not only regulate coal mine safety production, but also help scholars conduct safety technical research in these areas. Measures such as strengthening the material safety of transportation pipelines, using specialized leak monitoring devices, and properly configuring fire and explosion prevention devices can greatly reduce the incidence of safety accidents. Specifically, steel pipes should be used for the installation of safety facilities, while non-metallic pipes can be used for other conveying pipelines. The materials of conveying pipelines should be treated with anti-corrosion, anti leakage, anti smashing, and anti-static measures.

对发电机房和配电室等地配置的照明装置采用防爆灯具,设应急照明,在变压器上也要进行瓦斯、过流和速断等保护。而瓦斯抽采泵房、输气站加压机房和低浓度瓦斯管道系统中所选用的电气设备、仪表均应满足矿用防爆要求。非防爆设备和仪表应集中安设到专门的仪表间(或配电间),并采取相应的隔离措施和消防措施。

Explosion proof lamps should be used for the lighting devices installed in the generator room and distribution room, and emergency lighting should be installed. Gas, overcurrent, and quick break protection should also be carried out on the transformer. The electrical equipment and instruments used in the gas extraction pump room, gas transmission station booster room, and low concentration gas pipeline system should all meet the explosion-proof requirements for mining use. Non explosion-proof equipment and instruments should be centrally installed in specialized instrument rooms (or distribution rooms), and corresponding isolation and fire protection measures should be taken.

3 提高瓦斯利用度

3. Improve gas utilization

目前低浓度煤层气发电技术较成熟,发电机组运行功率一般为700kW。在实际应用中,各个煤矿的煤层规模、瓦斯浓度和瓦斯量等情况不同,需要不同功率和利用度高的机组来适应不同情况。可以从瓦斯抽采、输送和点燃利用全过程来降低瓦斯的损耗,提高可使用瓦斯的数量。或者使用智能控制技术来对瓦斯添加混合气进行精确控制,进而提高瓦斯气体的利用率。对于通风瓦斯,可以经过增压和浓度浓缩来进行利用。

At present, the low concentration coalbed methane power generation technology is relatively mature, and the operating power of the generator set is generally 700kW. In practical applications, the coal seam scale, gas concentration, and gas volume of each coal mine are different, requiring different power and high utilization units to adapt to different situations. The entire process of gas extraction, transportation, and ignition can be used to reduce gas loss and increase the amount of available gas. Alternatively, intelligent control technology can be used to precisely control the addition of mixed gas to gas, thereby improving the utilization rate of gas. For ventilation gas, it can be utilized through pressurization and concentration concentration.

扫一扫了解更多

扫一扫了解更多